About Us.

The Team

Established in 2019 and led by Chris & Steve, our team combines experience from the marine & industrial composites sectors.

Our strong background in professional sailing means we are accustomed to tight delivery deadline along with a broad range of skills and diverse strengths allow us to offer a well-rounded approach to any project.

We offer a 500m2 boutique facility which enables us to provide fit for purpose solutions for our clients and their projects.

Services & Capabilities

A strong focus on innovative processing solutions.

An agile workforce.

Large diameter composite autoclave in-house.

Component prototyping.

Tooling & fixture design.

3-axis CNC router cutting in-house.

Access to large format 5 axis CNC machining for tooling projects.

Connections with 3rd Party 3D modelling & composite engineering services.

Strong network of precision metal CNC machining suppliers.

Connections with NZ’s leading composite suppliers.

A strong relationship with CACM (Centre for Advanced Composite Manufacturing @ Auckland University) for mechanical testing & process validation.

Spars & Batten construction experience (conventional & wing).

Experience with high-tech appendage construction (AC33 tri, AC72 & AC50 class yachts).

Project Management.

Suppliers to the Marine, Industrial & Leisure markets.

Facilities

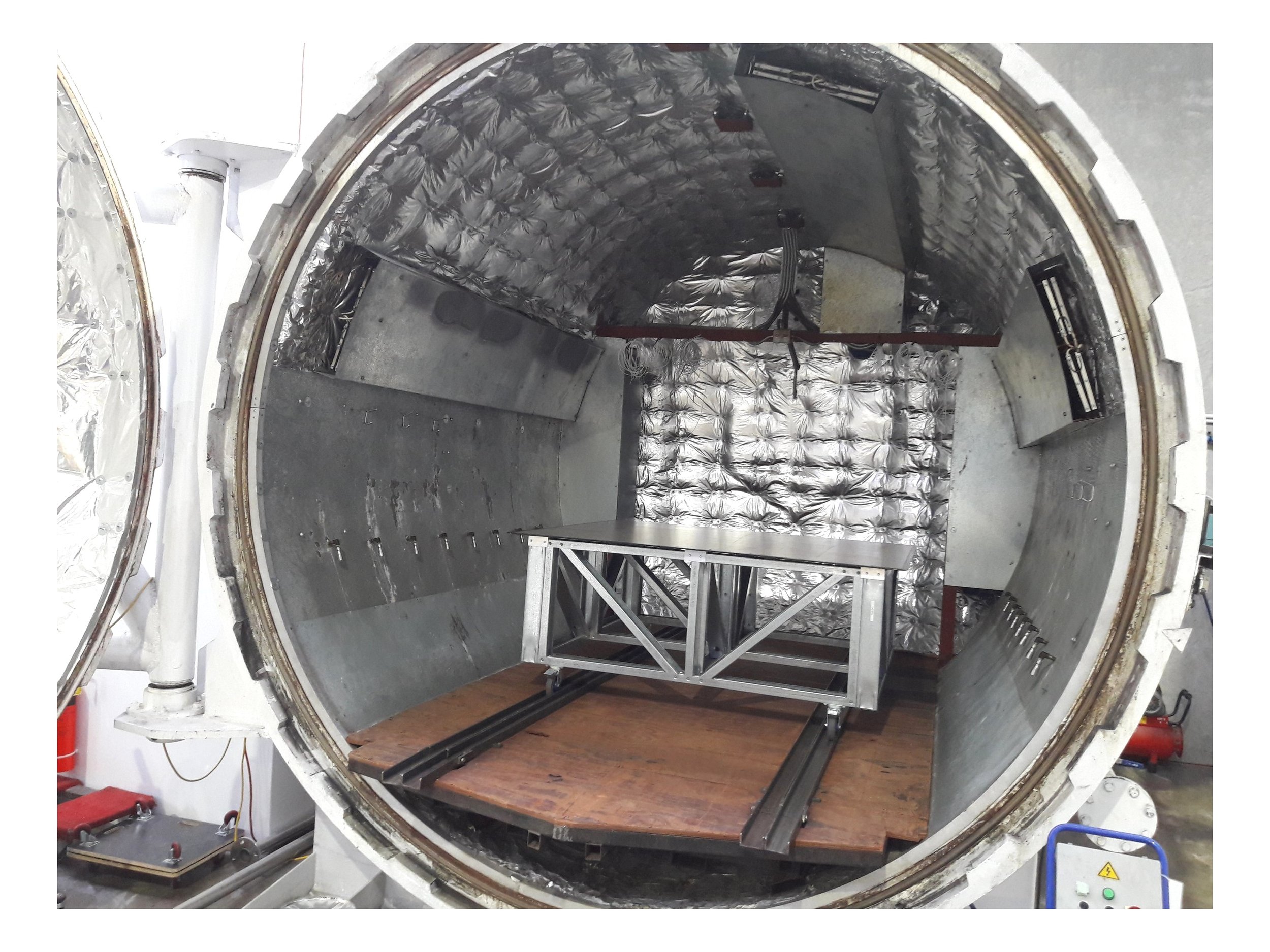

Autoclave

3.2 metre internal diameter.

4.5 metre length (dome).

Certified to 5 bar / 100C.

16 vacuum ports with dedicated pump.

10 logged thermocouples.

Programable cure cycles.

Contract autoclave curing

Process Rooms

2 x 6.8m(L) x 4.4m (W) x 3.0m (H) insulated ovens.

Partition wall allows ovens to be combined as one 13.8m x 4.4m space.

Temperature controlled environment.

8 channel thermocouple data-logger.

33Kw programmable electric heater.

Ring main vacuum system.

4Kw dedicated climate control per room.

Large Flat Vac Table - 5750mm x 2800mm

Trimming Room

Self-contained positive pressure room.

Dedicated extraction system with 0.2 micron filter system.

Fully plumbed for clean/dry air from large capacity compressor.

CNC Router

3-Axis CNC Router

2600mm x 1300mm x 400mm working envelope.

Tool manufacturing.

Post-mould part trimming & finishing.

Assorted mediums machined (Carbon, Tooling Boards, Plywood, MDF, UDF, Aluminium).

CNC drag knife cutting.

Vacuum hold down bed.

Dedicated extraction.

See our standard terms & conditions T&C's